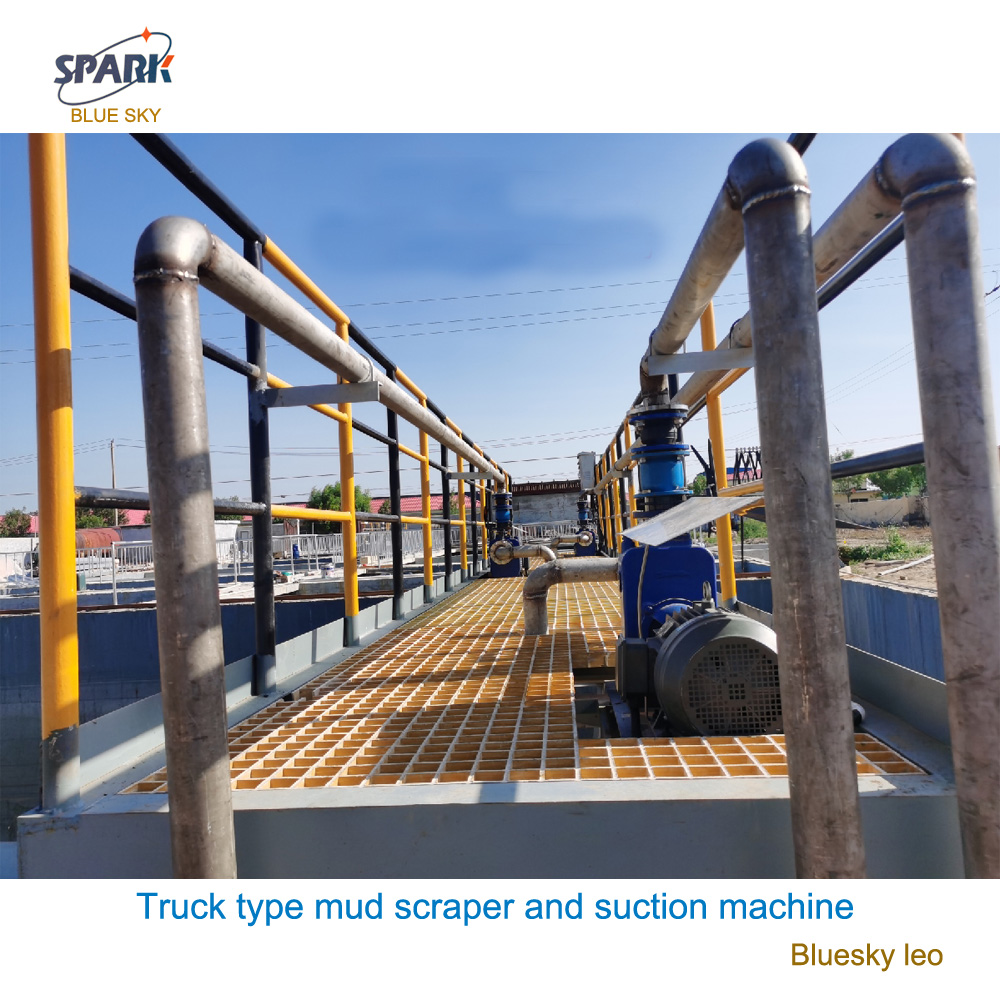

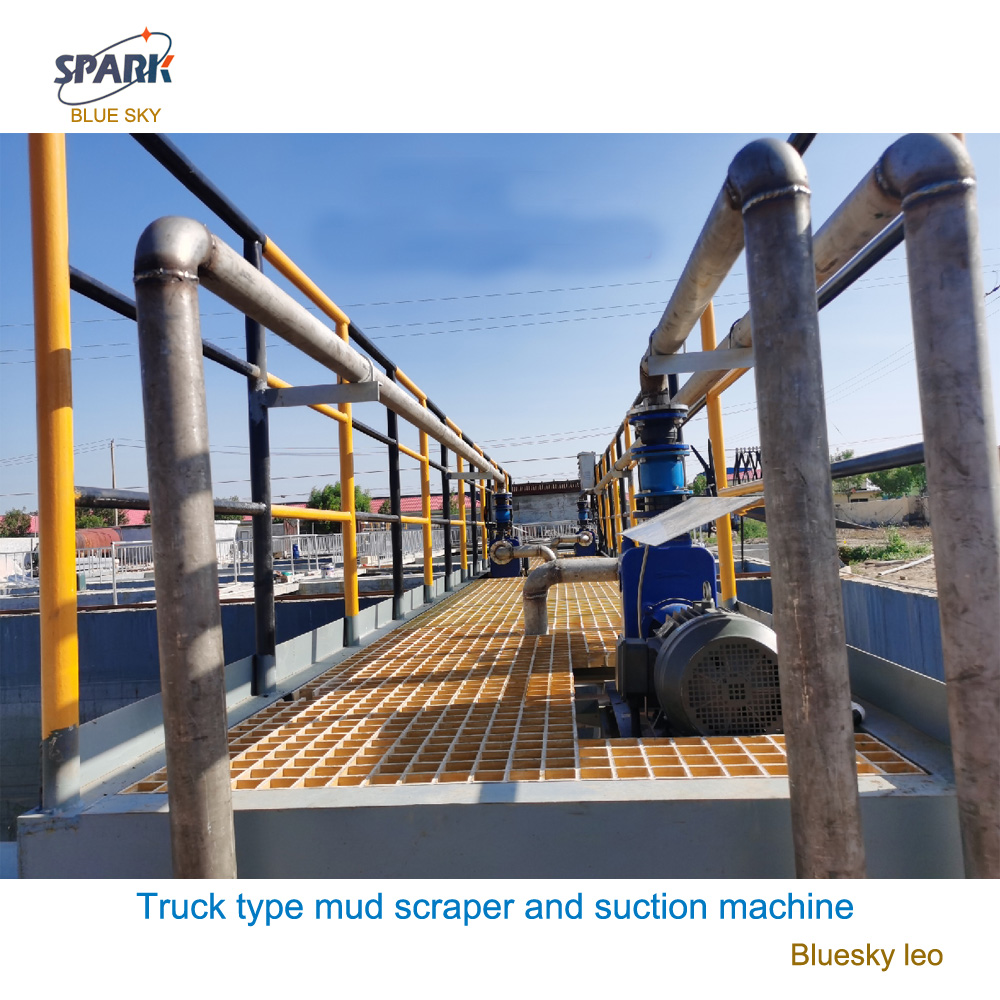

Travelling mud scraper & suction machine

Introduction to travelling mud scraper & suction equipmentI.Travelling mud scraper & suction machine is used in horizontal sedimentation tanks of Sewage Treatment and sewage treatment stations···

Introduction

Introduction to travelling mud scraper & suction equipment

I.Travelling mud scraper & suction machine is used in horizontal sedimentation tanks of Sewage Treatment and sewage treatment stations to scrape the settled sludge, sand, flocculants, etc. , by means of pumping or siphon, while walking while sucking mud, and then the sludge discharged from the pool, can remove the bottom of the sludge cleaning pain.

II. Structure principle travelling mud suction machine is composed of

1 working bridge,

2 driving walking device,

3 mud suction system,

4 slag skimming device (optional parts) ,

5 electric control cabinet, 6 hanger,

7 mud scraping plate,

8 electric control box,

9 mud discharging system, etc. .

III. Principle of structure

1.Working Bridge: Made of 32 # channel steel by welding. The structure strength is high, the chassis stability is good, the bearing capacity is big, provides the powerful guarantee for the traveling vehicle's stable movement. This equipment is supported by four points and runs across the Kaifeng River. It is driven on both sides of the horizontal sedimentation tank. Rails are laid on both sides of the tank and run from one end of the tank to the other end of the tank, return walk, return suction mud, complete a work cycle. Guardrail height 1.2 meters, yellow-black interval warning color, guardrail by DN25 and DN40 galvanized pipe composition, bottom with foot plate.

2, Drive Travel Device: the use of shaft-mounted reducer as the driving force, installed on the end of the beam, for the double-drive, compact structure, easy maintenance. The walking wheel is made of cast iron, with long service life and high stability, and it will not cause eccentric wear and derailment of the walking wheel.

3. Mud suction system: the mud suction system of this equipment is pump suction type. Pump-suction type according to the length of traffic can use two, four, Wutai, six, etc. (freely customized) submersible sewage pump or self-suction pump as a suction power, installed on the platform, connected with the sludge pipeline. When the train runs along the long direction of the tank, the sludge suction system will suck the sludge from the bottom of the tank into the pipeline and discharge it into the tank through the sludge discharge pipeline.

4. Slag skimming device: a slag skimming scraper is arranged on the mud scraper to scrape and collect the floating scum in the pond body to one end of the pond body, and then discharge the scum from the slag discharging device at one end of the pond body.

5, sludge pipeline: pump suction type with self-priming pump connected to the sludge pipeline, used to remove sewage pump suction into the pipeline sludge;.

6, hanger: with the platform connected to the crane, used to support the suspension suction pipeline and scraping mud plate, etc. . 7. The mud scraper: it is used to scrape and collect the sludge deposited on the bottom of the pond. The structure of the mud scraper is diamond-shaped, which can more effectively realize the function of scraping and collecting the sludge. The bottom end of the mud scraper has a certain distance from the bottom of the pond, so as to reduce the resistance of the equipment in operation, the utility model can make the sludge have better fluidity, and is convenient for the suction discharge of the submersible sewage pump or the self-priming pump pipe. If a mud collecting ditch is reserved at the bottom of the pond, the mud scraping board can be omitted and the sludge at the bottom of the ditch can be directly absorbed by a suction pipe.

8. Electric Control Box: this machine has the control function of manual, automatic, tight stop, reverse, cut off, delay and so on. It can set up start-stop period, realize periodic operation, avoid excessive sludge discharge and power waste. If failure or maintenance reasons can be closed by the stop button motor, to achieve an emergency cut-off. A delay device is arranged in the control box, and the delay time can be adjusted to control the time interval of the equipment running. In addition, there are suction pump on, stop and traffic sub-control, as well as leakage protection function.

9. Travel Control Device: it is installed at both ends of the driving device and collides with the limited protons on the rail to realize the reciprocating motion of the traveling vehicle. When running to both ends of the sedimentation tank, the vehicle can be stopped or reversed by limit switch.

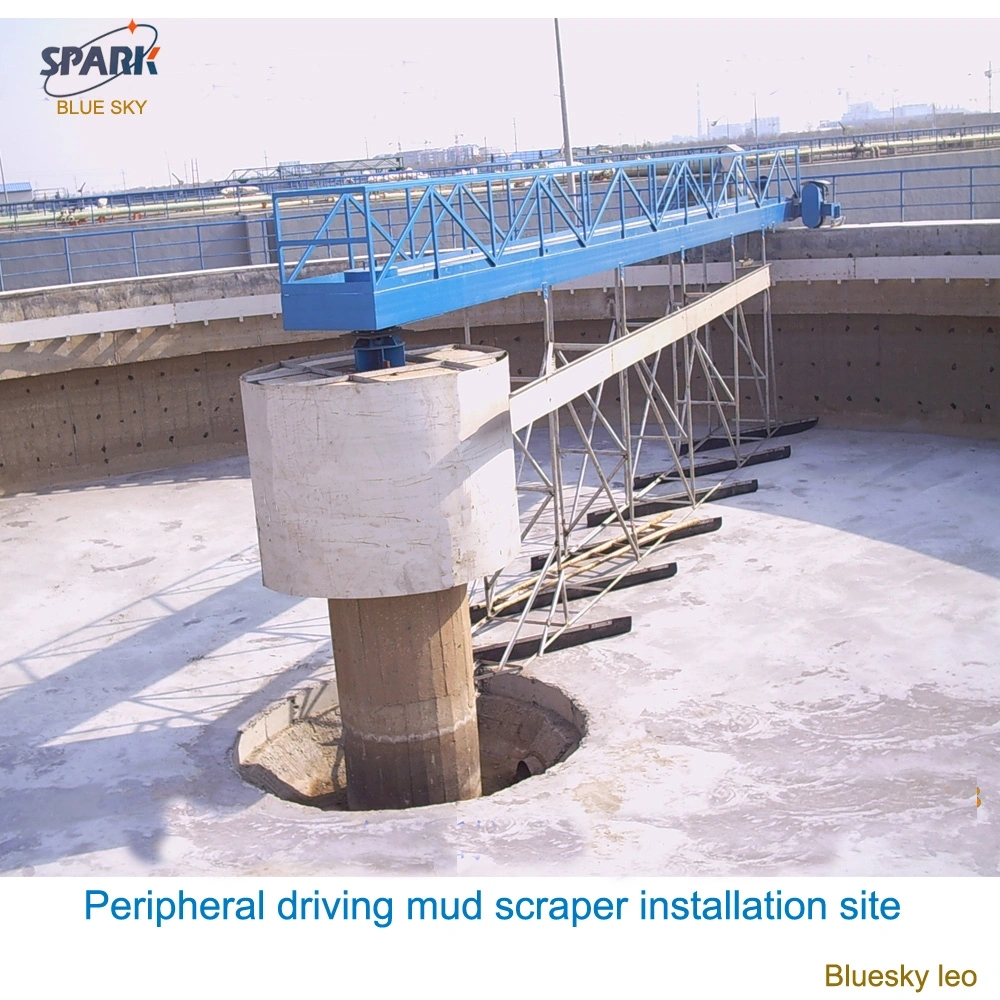

Photos